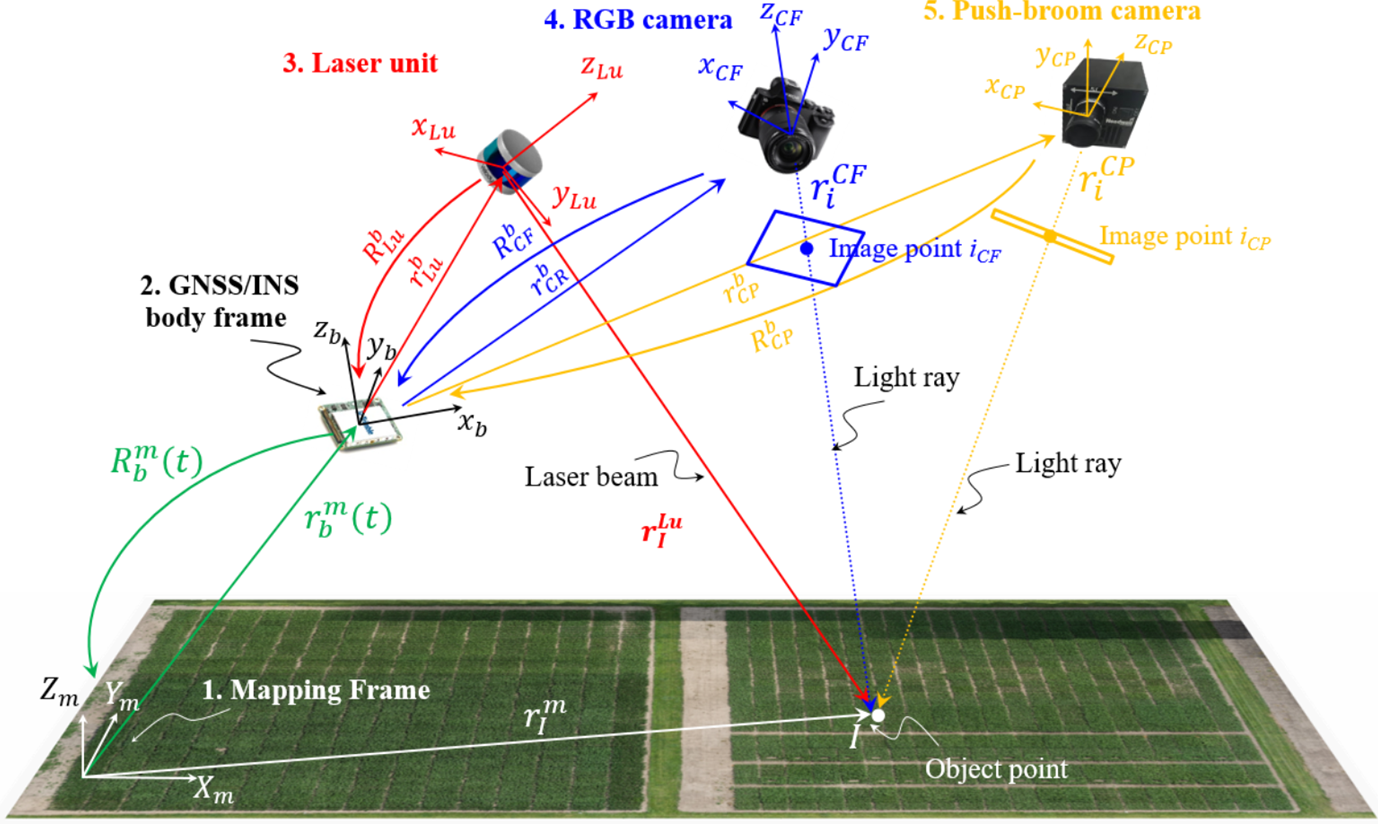

Boresight Calibration

Direct Georeferencing

Calibration Methods

Frame Cameras (GCP-Based)

Initial IOP Calibration

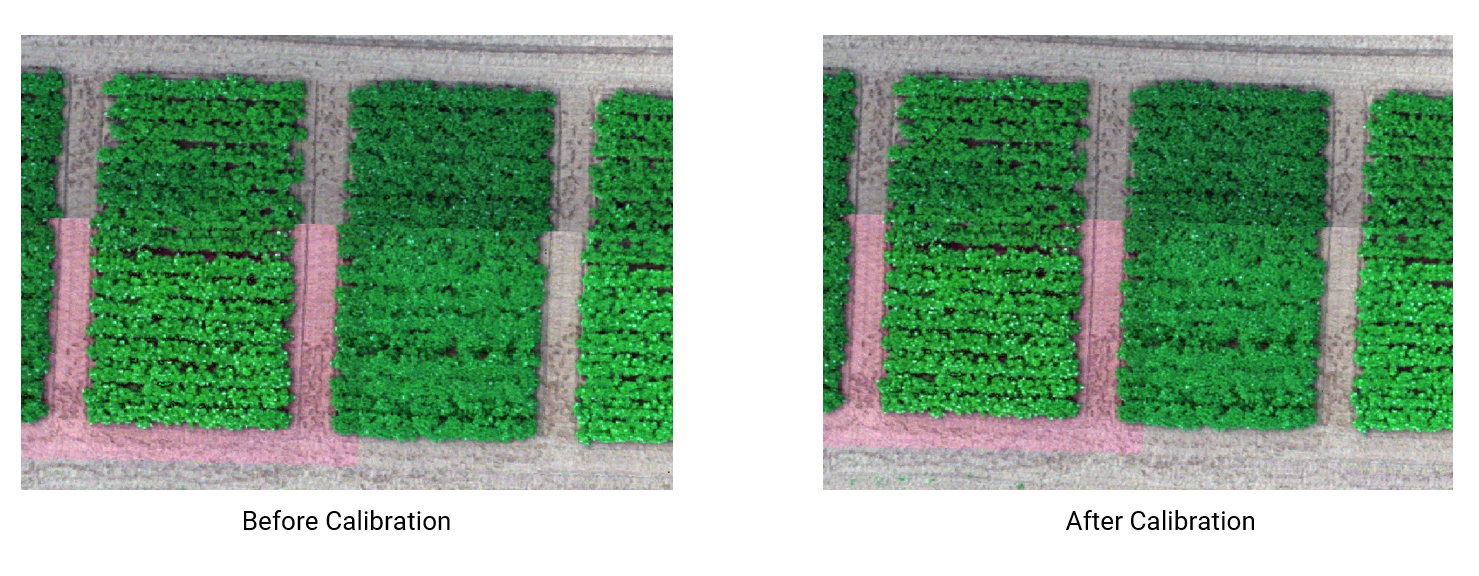

In-Situ IOP + Boresight Calibration

EOP Refinement

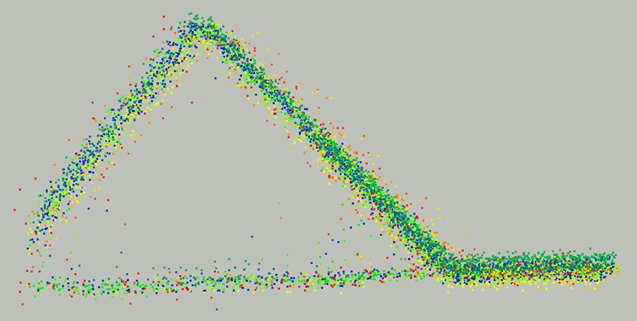

LiDAR (Profile-Based)

Push-Broom/Line-Scan Cameras (GCP-Based)

Last updated